Electric motors are everywhere! In your house, almost every mechanical movement that you see around you is caused by an AC (alternating current) or DC (direct current) electric motor. In this article we'll look at both types.

By understanding how a motor works you can learn a lot about magnets, electromagnets and electricity in general. An electric motor uses magnets to create motion. If you have ever played with magnets, you know about the fundamental law of all magnets: Opposites attract and likes repel.

So, if you have two bar magnets with their ends marked "north" and "south," then the north end of one magnet will attract the south end of the other. On the other hand, the north end of one magnet will repel the north end of the other (and south will repel south). Inside an electric motor, these attracting and repelling forces create rotational motion.

- Inside an Electric Motor

- How a DC Motor Works

- Toy Motor

- Rotor, Commutator and Brushes

- Putting it all together

- How an AC Motor Works

- AC Rotor and Stator

- Motors Everywhere!

Inside an Electric Motor

To understand how an electric motor works, the key is to understand how the electromagnet works.

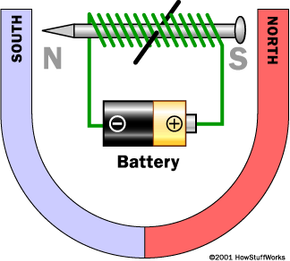

An electromagnet is the basis of an electric motor. Say that you created a simple electromagnet by wrapping 100 loops of wire around a nail and connecting it to a battery. The nail would become a magnet and have a north and south pole while the battery is connected.

Now say that you take your nail electromagnet, run an axle through the middle of it and suspend it in the middle of a horseshoe magnet as shown in the illustration. If you were to attach a battery to the electromagnet so that the north end of the nail appeared as shown, the basic law of magnetism tells you what would happen: The north end of the electromagnet would be repelled from the north end of the horseshoe magnet and attracted to the south end of the horseshoe magnet. The south end of the electromagnet would be repelled in a similar way. The nail would move half a turn and then stop in the position shown.

The key to an electric motor is to go one step further so that, at the moment that this half turn of motion completes, the field of the electromagnet flips. You flip the magnetic field by changing the direction of the electrons flowing in the wire, which means flipping the battery over. The flip causes the electromagnet to complete another half turn of motion. If the field of the electromagnet were flipped at precisely the right moment at the end of each half turn of motion, the electric motor would spin freely.

How a DC Motor Works

As we mentioned, you'll encounter two types of electric motors: direct current and alternating current. The latter, direct current, or DC, motors were first developed in the mid-1800s, and they're still in use today.

A simple motor has six parts:

- Stator

- Rotor

- Commutator

- Brushes

- Axle

- DC power supply

The outside of a DC motor is the stator: a permanent magnet that does not move. The inside part is the rotor, which does move. The rotor here is like the nail in our previous example, and the stator is like the horseshoe magnet.

When DC power is sent through the rotor, it creates a temporary electromagnetic field that interacts with the permanent magnetic field of the stator. The commutator's job is to keep the polarity of the field flipping, which keeps the rotor rotating. This creates the torque needed to produce mechanical power.

Toy Motor

The toy DC motor pictured is small, about as big around as a dime, with two battery leads. If you hook the battery leads of the motor up to a battery, the axle will spin. If you reverse the leads, it will spin in the opposite direction.

The nylon end cap is held in place by two tabs. Inside the end cap, the motor's brushes transfer power from the battery to the commutator as the motor spins. (Because brushes can wear out and need replacing, modern DC motors are often brushless.)

The axle holds the rotor and the commutator. The rotor is a set of electromagnets, in this case three. The armature in this motor is a set of thin metal plates stacked together, with thin copper wire coiled around each of the three poles of the rotor. The two ends of each wire (one for each pole) are attached to a terminal, and then each of the three terminals is wired to one plate of the commutator.

The final piece of any DC electric motor is the stator. In this motor, it's formed by the can itself plus two curved permanent magnets. In DC motors, the armature is the rotor, and the field is the stator.

Rotor, Commutator and Brushes

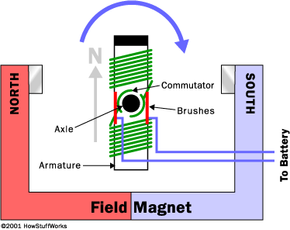

As we noted earlier, the rotor is like the nail in our diagram of an electromagnet. The commutator is also attached to the axle. The commutator is simply a pair of plates attached to the axle. These plates provide the two connections for the coil of the electromagnet.

The "flipping the electric field" part of an electric motor is accomplished by two parts: the commutator and the brushes.

The diagram shows how the commutator (in green) and brushes (in red) work together to let current flow to the electromagnet, and also to flip the direction that the electrons are flowing at just the right moment. The contacts of the commutator are attached to the axle of the electromagnet, so they spin with the magnet. The brushes are just two pieces of springy metal or carbon that make contact with the contacts of the commutator.

Putting It All Together

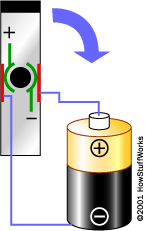

When you put all of these parts together, what you have is a complete electric motor.

The key is that as the rotor passes through the horizontal position, the poles of the electromagnet flip. Because of the flip, the north pole of the electromagnet is always above the axle so it can repel the stator's north pole and attract the stator's south pole.

Usually the rotor will have three poles rather than the two poles as shown in this article. There are two good reasons for a motor to have three poles:

- It causes the motor to have better dynamics. In a two-pole motor, if the electromagnet is at the balance point, perfectly horizontal between the two poles of the stator when the motor starts, you can imagine the rotor getting "stuck" there. That never happens in a three-pole motor.

- Each time the commutator hits the point where it flips the field in a two-pole motor, the commutator shorts out the battery for a moment. This shorting wastes energy and drains the battery needlessly. A three-pole motor solves this problem as well.

It is possible to have any number of poles, depending on the size of the motor and what it needs to do.

How an AC Motor Works

Now, we're going to look at the AC motor. AC motors use alternating current instead of direct current. It shares many parts with a DC motor, and it still relies on electromagnetism and flipping magnetic fields to generate mechanical power.

The parts inside an AC motor are:

- Stator

- Rotor

- Solid axle

- Coils

- Squirrel cage

The winding of the stator in an AC motor kind of does the job of the rotor of a DC motor. In this case, it's a ring of electromagnets that are paired up and energized in sequence, which creates the rotating magnetic field.

You'll remember that the rotor in a DC motor is hooked up to the battery. But the rotor in an AC motor does not have any direct connection to a power source. Nor does it have brushes. Instead, it often uses something called a squirrel cage. You read that right.

The squirrel cage in an AC motor is a set of rotor bars connected to two rings, one at either end. It's kind of like something a caged mouse (or squirrel) would run inside. The squirrel cage rotor goes inside the stator. When AC power is sent through the stator, it creates an electromagnetic field. The bars in the squirrel cage rotor are conductors, so they respond to the flipping of the stator's poles. That's how the rotor rotates, which creates its own magnetic field.

AC Rotor and Stator

The key to an AC induction motor, where the field of the rotor is induced by the field of the stator, is that the rotor is always trying to catch up. It's always looking for stasis, so it's rotating to find that steady state. But the electromagnetic field produced by the stator using AC power is always going to be a little faster than the rotor's field. The spin of the rotor is creating the torque needed to create mechanical power to turn the wheels of a car or the whirr of a fan.

Some AC motors use a wound rotor, which is wrapped with wire instead of being a squirrel cage. The squirrel cage kind is more common, though. In either case, there's only one moving part in an AC motor, which means there are fewer things that need replacing or maintenance.

Motors Everywhere!

Look around your house and you will find that it is filled with electric motors. Since our homes use AC power, most of these gadgets have AC motors. DC motors are more likely to be found in things that use batteries. Starting in the kitchen, there are motors in:

- The fan over the stove and in the microwave oven

- The blender

- The refrigerator - Two or three in fact: one for the compressor, one for the fan inside the refrigerator, as well as one in the icemaker

- The stand mixer

In the utility room, there is an electric motor in:

- The washer

- The dryer

- The electric screwdriver

- The vacuum cleaner

- The electric drill

- The furnace blower

Even in the bathroom, there's a motor in:

- The fan

- The electric toothbrush

- The hair dryer

- The electric razor

Your car is loaded with electric motors:

- Power windows

- Power seats

- Fans for the heater and the radiator

- Windshield wipers

- The starter motor

- An AC motor might power your car rather than a gasoline engine

Plus, there are motors in all sorts of other places:

- Computers

- Smartphones

- Toys

- The garage door opener

- Aquarium pumps

Almost everything that moves uses an electric motor to accomplish its movement.